The Helper Machinery Fully Automatic Frozen Cooked Noodle Production Line Solution is designed for modern noodle processing factories, central kitchens, and prepared food manufacturers.

I. Solution Overview

The Helper Machinery Fully Automatic Frozen Cooked Noodle Production Line Solution is designed for modern noodle processing factories, central kitchens, and prepared food manufacturers.

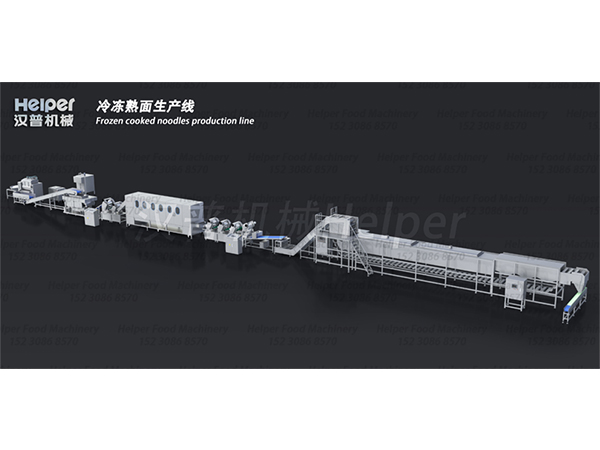

We provide a one-stop turnkey project service, covering the entire process from raw material feeding to frozen finished product output.

Independently developed and manufactured by Helper Machinery, the complete production line integrates automation control technology, precision transmission systems, and food-grade hygienic structural design.

It realizes continuous and fully automated production including dough preparation, noodle forming, portioning, automatic cooking, intelligent packaging, and rapid freezing — significantly increasing production efficiency, reducing labor costs, and ensuring consistent product quality.

II. Process Flow

Automatic Feeding → Vacuum Dough Mixing → Dough Resting & Maturation → Multi-stage Rolling → Sheet Forming → Portion Cutting → Automatic Cooking → Cooling & Dewatering → Automatic Packaging → Tunnel Freezing → Finished Product Conveying & Storage

III. System Composition

1. Dough Preparation System

Vacuum Dough Mixer + Dough Resting & Maturation Unit

Ensures precise water dosing, uniform mixing, and controlled temperature & humidity resting to form a stable gluten structure.

2. Rolling & Forming System

Multi-stage Compound Roller + Sheet Forming Machine

Progressive rolling with adjustable thickness, producing smooth noodle sheets with excellent extensibility.

3. Portion Cutting System

High-precision Cutting & Weighing Device

Automatically divides noodles into fixed-weight portions to meet different packaging specifications.

4. Automatic Cooking System

Continuous Cooking Tank + Temperature Control System

Accurately controls cooking time and temperature to ensure uniform doneness.

5. Cooling & Dewatering System

Cold Water Spraying + Vibrating Dewatering Unit

Rapidly cools noodles and removes surface moisture to prevent sticking.

6. Automatic Packaging System

Intelligent Robotic or Automatic Tray Loading Unit

Automatically places noodles into trays or bags, improving packaging efficiency.

7. Rapid Freezing System

Spiral or Tunnel Freezer

Quickly passes through the ice crystal formation zone to lock in moisture and texture.

8. Intelligent Control System

PLC Central Control + Touch Screen Operation

One-button operation, recipe parameter storage, and remote diagnostic support.

IV. Solution Advantages

✔ Fully Automated Process — Minimal manual intervention from feeding to frozen output

✔ Stable Product Quality — Digital control of key processing stages

✔ High Production Capacity — Continuous operation for industrial-scale production

✔ Energy-efficient Design — Optimized heat recovery and power management

✔ Food Safety Compliance — 304 stainless steel structure, compliant with HACCP & CE standards

✔ Flexible Customization — Capacity, process, and packaging formats customizable

✔ Turnkey Delivery — Factory layout design, installation, commissioning, and staff training

V. Applicable Products

Frozen Ramen

Frozen Udon

Frozen Pasta

Instant Cooked Noodles

Prepared Meal Noodle Products

VI. Target Customers

✔ Frozen Food Processing Plants

✔ Central Kitchens

✔ Prepared Meal Manufacturers

✔ Chain Restaurant Supply Centers

✔ Noodle Export Processing Enterprises

VII. Service Support

Factory Layout Planning

Process Parameter Setup

Installation & Commissioning

Operator Training

Remote Technical Support

After-sales Service & Spare Parts Supply

Helper Frozen Cooked Noodle Solution — From flour to frozen finished noodles, fully automated, highly efficient, consistently reliable, and easily replicable.